Our Core Products

Satisfying customers is the only reflection of our value

ACCESSORIES

About Us

We want to give you the best services

With over 25 years in the water jet cutting industry, WIN-WIN Company remains focused exclusively on this field. We boast extensive experience in diverse cutting applications, including automotive interiors, metals, ceramic tiles, glass, rubber, and pipes.

Guaranteed Results

+ 25 Year Experience

Quality Services

+ 1200 Happy Clients

Solution

Satisfying customers is the only reflection of our value

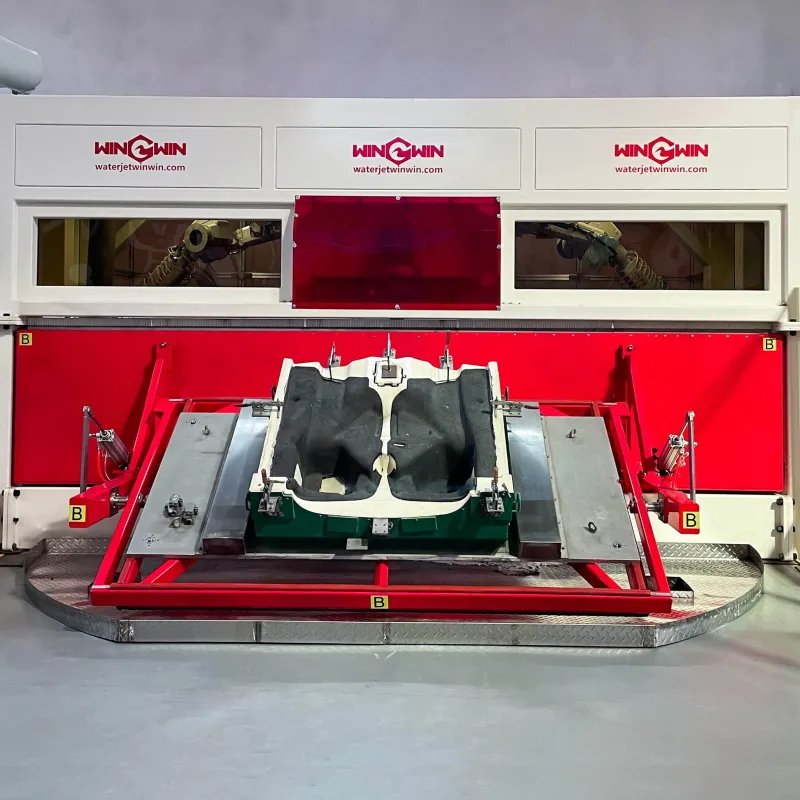

Our Large-Platform Waterjet Cutting Machine

Boasts high-stroke Z-axis, bridge structure, modular X/Y axes (up to 40m Y), optional multi-axes—ideal for drone wings and wind turbine blades..

Our Large-Platform Waterjet Cutter

Features flexible modular design, high-stroke Z-axis and bridge structure—ideal for large components like drone wings and wind turbine blades.

Frequently Asked Questions

Have Any Questions For Us?

We provide targeted solutions for industrial scenarios by relying on reliable robotic automation technology and continuous technological innovation, addressing core pain points in production and operation.

What types of manufacturing services do you provide?

Our manufacturing services focus on precision waterjet cutting for diverse materials—including metals, composites, stone, glass, and plastics. We offer custom fabrication, prototyping, and batch production, with capabilities for intricate designs and thick material processing to meet unique project specs.

Which industries do you serve with your factory solutions?

Our factory solutions serve a wide range of industries, including metal fabrication, aerospace, automotive, and construction. Our waterjets excel at cutting thick metals, alloys, and even heat-sensitive materials, making them ideal for precision parts in these sectors.

What certifications and quality standards do you follow?

Our certifications include ISO 9001 (quality management system), CE marking (for safety and performance in the EU), and RoHS compliance (restricting hazardous substances). We also follow ASTM standards for material cutting precision and maintain internal quality protocols that exceed many industry benchmarks.

Could you help us with on-site equipment debugging?

Absolutely! We offer on-site equipment commissioning as part of our service. Our technical specialists will travel to your facility to set up the waterjet, calibrate parameters, test operations, and ensure it runs at peak efficiency. Just let us know your schedule, and we’ll arrange it promptly

How long does it take to complete a typical project?

A typical project timeline varies based on factors like material type, thickness, cut complexity, and batch size. For small to medium jobs (e.g., 10-50 parts in metal/composites), our waterjets often finish in 1-3 days thanks to high-speed cutting and precision.

Testimonials

Satisfying customers is the only reflection of our value

What Say Clients

News & Blogs

Satisfying customers is the only reflection of our value

Our Latest News and blogs

/

Contact Us

Satisfying customers is the only reflection of our value